Randall is a chair made of polypropylene, an extremely light and easy to paint material. Its lightness was obtained through iterative processes of optimization, so that the seat turned out to be empty inside. The chair matches with any kind of furniture and becomes the centerpiece of infinite solutions to furnish a living room or studio.

Initial mechanical analyses involved different materials: polypropylene, polymethylmethacrylate, ABS and aluminum. In conclusion, the material we chose is polypropylene. The shape does not contain points that require additional padding, as this would affect the homogeneous and clean design that we wanted to give to Randall.

Randall

Autodesk Fusion 360, Keyshot.

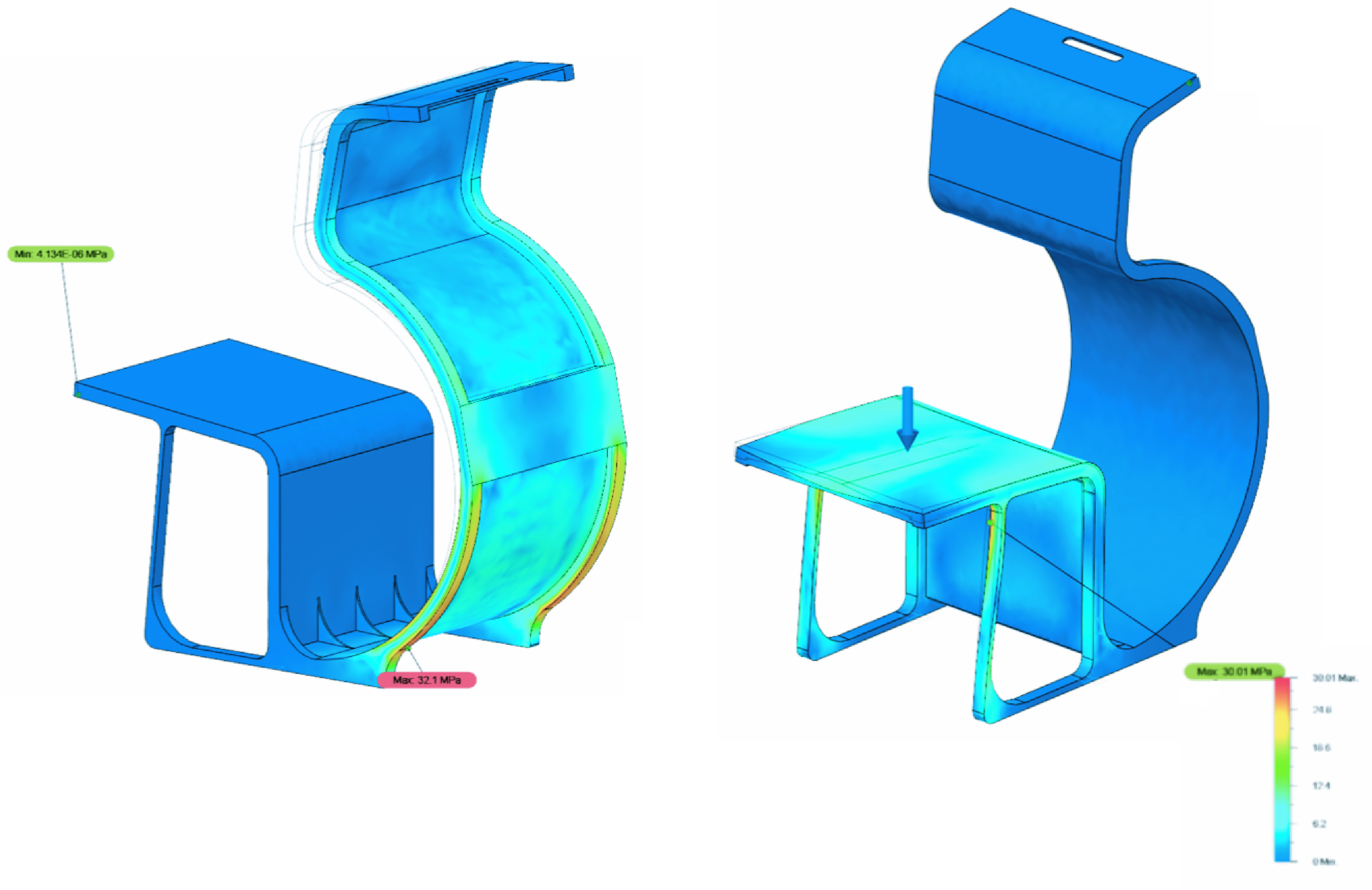

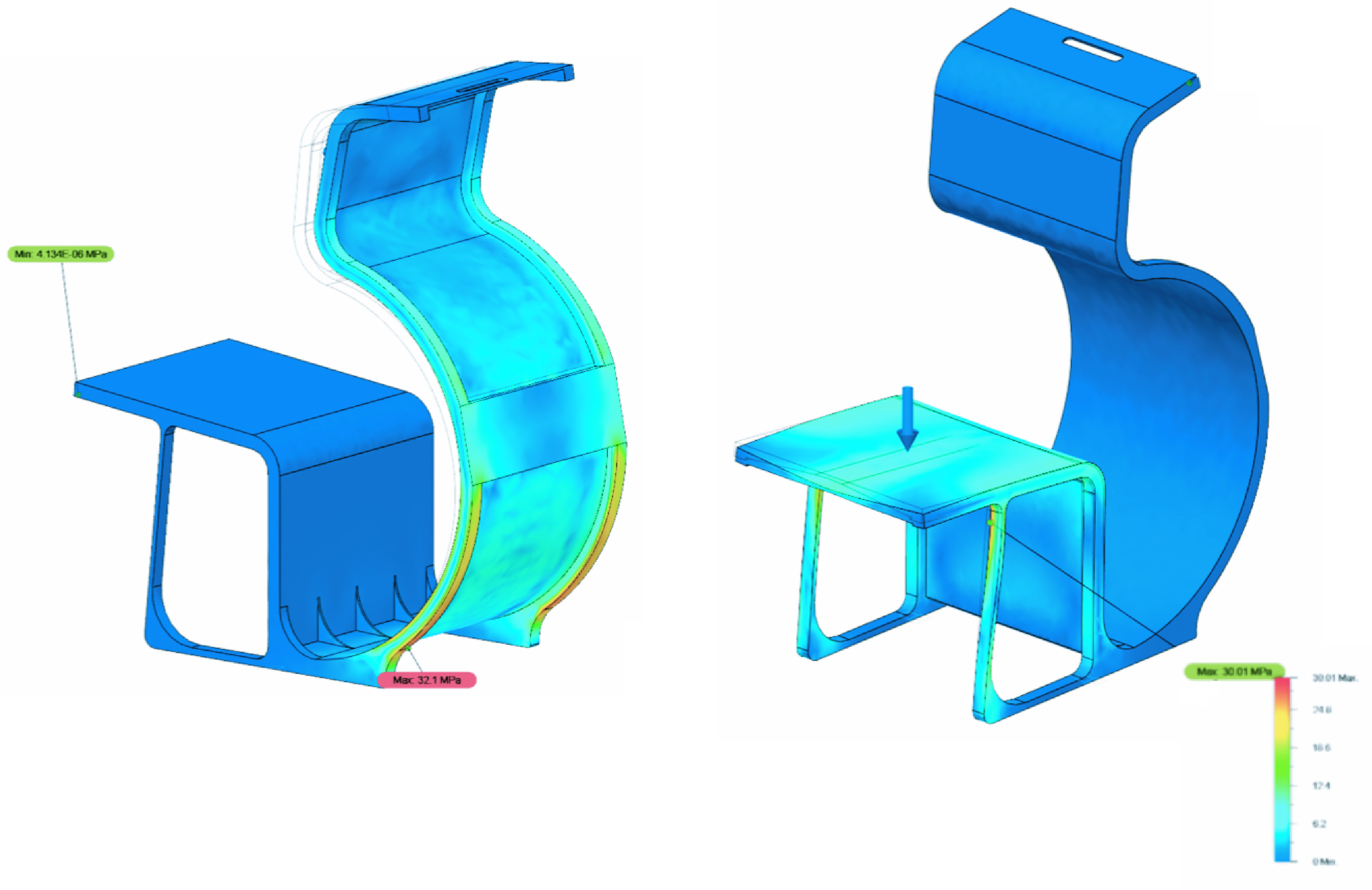

Randall weighs 14 Kg made with PP. The following pictures show how the material performs on the final design. On the left, the "A" position can bear a maximum load on the seat of 3750 N (375 kg), and on the backrest 400 N (40 kg).

In the B position, the maximum load limit on the seat is 1800 N (180 kg) while on the backrest is 400 N (40 kg).

The values of the limit forces resulting from the tilting moment tests have been determined. These tests have the purpose of identifying forces that, if applied in specific points, can tilt the chair.

The data used for the calculations are the mass of the seat (14KG), the position of the applied forces and the position of the center of gravity of the object.